Corzan® CPVC Reliably Handles Nitric Acid Better Than Stainless Steel

One of the greatest challenges to the construction and engineering industries is a shortage of skilled labor. Stainless steel piping requires a lot of skilled-labor time to install, which has already gotten more expensive and may increase lead times. CPVC avoids these problems without compromising performance against harsh industrial chemicals like nitric acid.

Nitric acid is a highly corrosive mineral acid. It is strongly oxidizing, attacks most metals and can lead to degradation of plastics.

No single material will be right for every project where nitric acid is used. But for many applications and industries, Corzan® CPVC provides superior performance, reliability, service life and – especially compared to stainless steel – cost savings for material expense, installation and maintenance.

What Does Nitric Acid Do to Metal?

The speed and intensity of corrosion depend on the concentration and temperature of nitric acid, the presence of impurities and the type of piping material.

Many industries can rely on carbon steel piping, but it is well known that nitric acid quickly deteriorates standard carbon steel. Nitric acid causes an oxidation-reduction (redox) reaction when it touches carbon steel. The iron in the piping oxides, and the nitric acid reduces into nitrogen dioxide or other nitrogen oxide gases. Nitric acid attacks the iron matrix of carbon steel, which degrades and weakens the steel and contaminates the nitric acid. Because of all this, engineers know not to specify carbon steel for nitric acid conveyance.

Stainless steel is much more resilient against nitric acid due to its chromium content, alloying elements, and its ability to be passivated when free of contaminants. It is very important to ensure stainless steel is fully passivated to achieve the highest corrosion resistance. Standard grades of the most common stainless steel, austenitic, contain a maximum of 0.08% carbon, reducing its reactivity with harsh acids. But this comes at a cost: Stainless steel can be four times more expensive than carbon steel, and the prices between high-carbon grade (H Grade) and more resilient low-carbon grade (L Grade) stainless steel can vary by 40%.

The cost of stainless steel buys more time, but it can't delay the inevitable. It will still suffer pitting and stress corrosion and will require expensive, high-skill maintenance over its service life.

What Does Nitric Acid Do to Plastics?

Not all plastics can hold up to harsh acids, because not all plastic piping can handle strong oxidizers. But Chlorinated polyvinyl chloride or CPVC and Polyvinylidene difluoride or PVDF are great candidates because of their inherent corrosion resistance to chemicals like nitric acid.

PVDF, is a high-performance thermoplastic. It is non-reactive and has low levels of impurities. This makes PVDF highly suitable for nitric acid metal etching in the electronics, semiconductor, food and beverage processing and medical device industries, which require the very strictest purity levels.

PVDF is chemically resistant to nitric acid, but it is not commonly specified for two reasons: First, PVDF is typically produced in up to four-inch diameters and is thus more commonly used for drains. Second, its material costs are more expensive than stainless steel. Except for those highest-purity applications, the costs of PVDF often outweigh the benefits of using a known material like stainless steel for nitric acid.

CPVC is an equally reliable but much more affordable alternative to stainless steel. High-quality CPVC like Corzan CPVC has a high level of chlorine on the polymer chain which protects its molecular structure from corrosive chemicals and is a reliable but much more affordable alternative to stainless steel or PVDF. With a price tag around that of carbon steel piping, Corzan CPVC is about four times less expensive than stainless steel and PVDF. And this is just the material expense: CPVC has lower installation and maintenance costs compared to metal and specialty plastics:

- Compared to metals, CPVC is very lightweight. This means it can be brought to the site in fewer truckloads, installed in fewer hours and requires fewer laborers.

- CPVC has multiple joining methods. Unlike the highly skilled labor needed to weld stainless steel during installation and maintenance, CPVC can be joined by solvent welding, or mechanical joint which is much faster to gain proficiency in performance and can be completed in a few minutes per weld.

One of the greatest challenges to the construction and engineering industries is a shortage of skilled labor. Stainless steel piping requires a lot of skilled-labor time to install, which has already gotten more expensive and may increase lead times. CPVC avoids these problems without compromising performance against harsh industrial chemicals like nitric acid.

Corzan CPVC Stands Up to Nitric Acid

Lubrizol has pioneered CPVC technology for over 60 years. These decades of expertise have yielded a superior compound that is precisely engineered and real-world tested and undergoes strict quality assurance processes to make it the premier CPVC material available.

Corzan CPVC has excellent resistance to nitric acid in many industrial applications when specified appropriately and correctly installed.

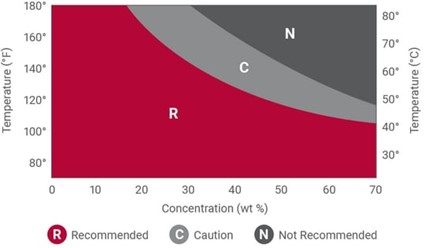

Corzan CPVC has been tested and proven as recommended for use with nitric acid at a broad temperature and concentration range

Corzan CPVC has been tested and proven as recommended for use with nitric acid at a broad temperature and concentration range

Like all materials, CPVC will degrade at certain concentrations, temperatures and over time. Corzan CPVC will not corrode, but whitening and etching of the material surface can happen if temperature and concentration levels are too high. Reducing application temperature where possible can help to slow the degradation mechanism to an acceptable rate.

Corzan CPVC is a cost-effective alternative to stainless steel for many industries using nitric acid in their processes, including:

- Chemical processing

- Semiconductors, particularly in etching and chemical waste

- Fertilizer production

- Metallurgy and mining, especially as an etchant and for passivation

- Explosives production, like TNT

- Some firearm and defense etching (e.g., serial numbers and other customization)

- Some automotive, aerospace and aviation etching

The right piping material is critical to ensure piping systems run smoothly, safely and cost efficiently. While nitric acid is dangerous, it is one of the top 10 commonly used chemicals that Corzan CPVC is more suitable for compared to metals and other plastics.

Learn more about Corzan CPVC and nitric acid.