CPVC Resistance to Acids: Sulfuric, Nitric, Hydrochloric and Phosphoric

Acids are commonly used by industrial plants for a range of applications, from pH adjustment to the manufacture of other important industrial chemicals. Some of the most common acids include: sulfuric, nitric, hydrochloric and phosphoric.

These acids are aggressive substances that can be highly corrosive to certain materials. Metals tend to corrode quickly when exposed to acids relative to some thermoplastics. In addition, the high pressure and heat of many industrial processes tend to escalate this corrosion.

In the case of high-quality CPVC, the high level of chlorine in the polymer chain helps protect it from the degrading effects of acids. That said, material degradation and corrosion can occur over time. The severity is largely based on material quality and operating temperature, as well as acid concentration and type.

Because of the corrosiveness of mineral acids, special considerations must be made when transferring and storing them in an industrial facility.

CPVC Breakdown

Prior to diving into CPVC’s compatibility with specific acids, we must address how chemicals can affect CPVC material. Chemical attack of CPVC occurs by way of two primary mechanisms: general degradation and localized stress corrosion cracking.

- General Degradation: General degradation occurs when the CPVC resin or compounding ingredients in the material are altered or destroyed by a chemical. This degradation is often characterized by discoloration and blistering of the pipe, sheet, or liner surface.

- Localized Stress Corrosion Cracking: Localized CPVC stress corrosion cracking follows a mechanism similar to stress corrosion of metals. Localized stress in a CPVC material can enhance the effects of chemical attack, encouraging crack propagation from the weakened area.

The severity of degradation is often contingent on temperature, pressure, concentration of the medium, strain applied to the material, manufacturing quality, fabrication quality, and the quality of the CPVC compound.

Is CPVC the Right Choice for Your Application?

Corzan® Industrial Systems provides a general resistance rating of our material with specific acids. In addition, our engineering team recommends customers check with the manufacturer of piping, sheet, and lining products for resistance.

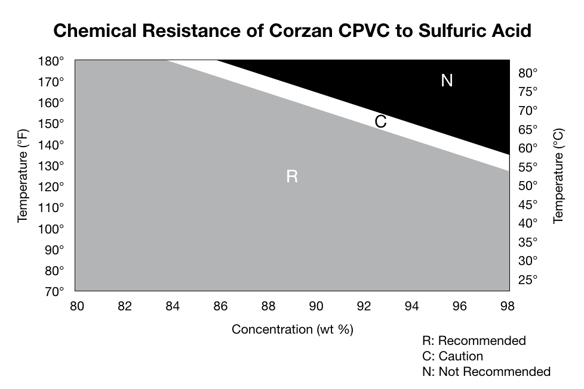

Sulfuric Acid and CPVC

Sulfuric acid (H2SO4) is a strong acid and widely used across a number of industries. Most sulfuric acid is produced at between 93 and 98% concentration, but can be diluted based on the application. In sulfuric acid applications especially, CPVC compound and product quality matter. The importance of quality increases as the heat and acid concentration rise.

A pipe made from low-quality CPVC resin and compounding ingredients is far more susceptible to the degrading effects of sulfuric acid, sometimes lasting only a few months. Sulfuric acid has also been known to attack CPVC in areas where optimal fusion wasn’t achieved during manufacturing or fabrication. Proper processing techniques and high-quality material can provide a long, reliable service life, potentially lasting years longer than metal alternatives.

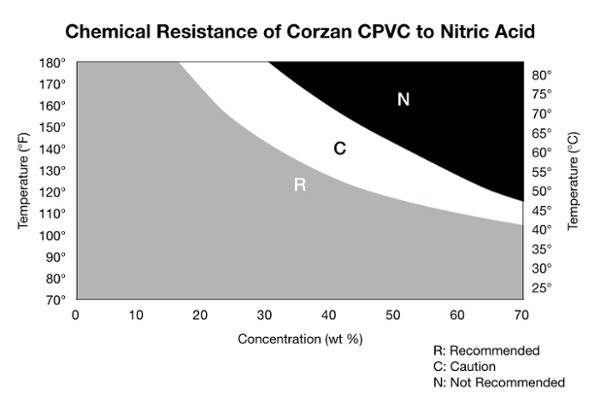

Nitric Acid and CPVC

Nitric acid (HNO3) is a strong acid that is most commonly available in concentrations up to 68%. CPVC degradation caused by nitric acid comes in the form of whitening and etching of the material surface. Corzan CPVC offers excellent resistance to nitric acid degradation to a point, but as temperature and concentration increase so does the degradation.

For this reason, Corzan Industrial Systems recommends reducing application temperature if possible, as this can help to slow the degradation mechanism to an acceptable rate.

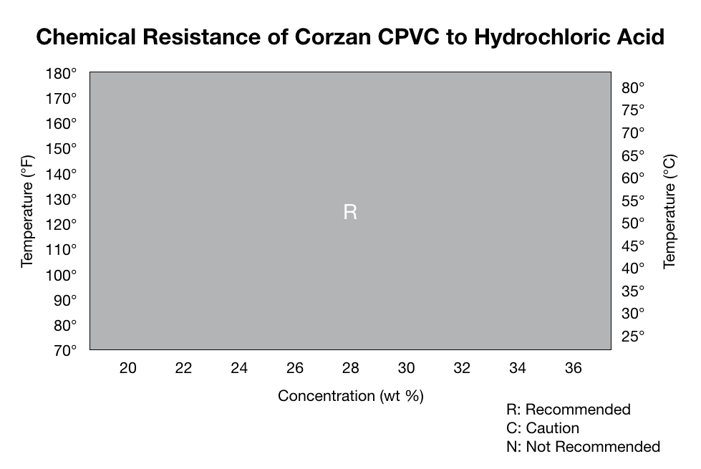

Hydrochloric Acid and CPVC

Hydrochloric acid (HCl) is a widely used, strong acid that is typically produced in concentrations up to 38%. Corzan CPVC offers excellent resistance to all concentrations of HCl within the material’s normal operating temperature range.

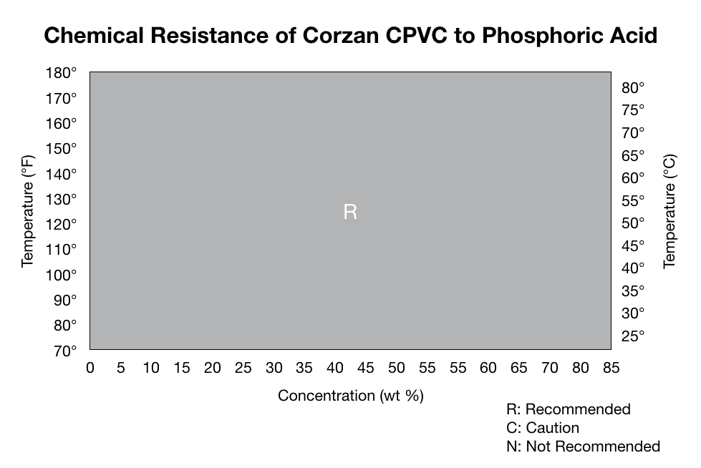

Phosphoric Acid and CPVC

Phosphoric acid (H3 PO4) is considered a weak acid, but can still be corrosive to certain materials. Corzan CPVC has excellent resistance to all concentrations of phosphoric acid within the material’s overall working range.

Corzan® CPVC in Acid Applications

For more information on Corzan CPVC’s capabilities for acid applications, check out the following case studies and resources:

- Can CPVC Piping Systems be Applied in Sulfuric Acid Plants?

- Leading Litho Plant Expands Use of CPVC Piping to Reduce Maintenance Costs and Downtime

- Thorpe Plant Services Turns to +GF+ Corzan CPVC to Meet Needs for Hydrochloric Acid Handling

- Thermoplastic Piping Systems and Mitigating Corrosion

Or, view the Corzan CPVC Chemical Resistance table, which analyzes Corzan CPVC's resistance to more than 400 chemicals and compounds.