Why CPVC Is Ideally Suited for the Chemical Processing Industry

The following is an excerpt from “CPVC Use in the Chemical Processing Industry.” Download the full ebook to learn more about where CPVC can be used in the chemical processing industry, which chemicals CPVC stands up against and how CPVC compares to alternatives in various applications.

The chemicals market, according to Chemical Processing, is currently worth around $1 trillion and is projected to grow to more than $5 trillion by 2022. With 40,000 existing facilities—and thousands more planned—the chemical processing industry (CPI) is becoming increasingly competitive.

Broadly defined as the chemical conversion of raw materials to finished products, the Chemical Processing Industry includes the following (and much more):

- Traditional chemicals, both organic and inorganic

- Petroleum

- Petrochemical

- Refining

- Pharmaceutical facilities

- Marine support and offshore

In this growing sector, plant managers and engineers seek systems that are more cost effective, reliable and specially engineered to meet their process’ demands. What is the role of piping material selection in recognizing greater plant performance and reliability?

Traditional Options

Chemical processing plants involve aggressive chemicals and high temperatures, often causing corrosion, process leaks and premature failures.

Many plants traditionally use alloys, such as carbon steel or stainless steel. These metals offer inherent strength and, most importantly, the industry is familiar with their performance—both strengths and weaknesses. Misapplication of these materials may require regular replacement every few years.

As the chemical industry continues to specialize in advanced chemistries, the need for piping materials that can handle the full pH range grows.

A Reliable Alternative: CPVC

Many alternative materials are ideally suited for chemical processing applications. These systems can operate reliably for decades, resulting in material cost savings, installation cost savings and less downtime.

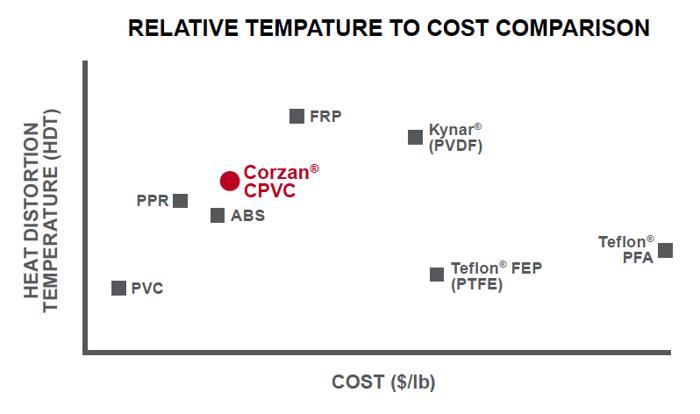

Chlorinated polyvinyl chloride (CPVC) is a specially engineered thermoplastic that has become an industry standard material. It satisfies the need for reliable piping systems and provides a balance between performance and costs. It offers excellent corrosion resistance to a broad range of chemicals, and better impact strength and temperature resistance than many other nonmetallic materials.

Additionally, traditional alloys can suffer when faced with corrosive acids, bases and salts. Even water can rapidly decrease the material’s life. CPVC eliminates internal and external corrosion, and inherently withstands corrosion from a wide range of acids, bases and salts, even at elevated temperatures. Some notable CPI chemicals it is compatible with include:

- Sodium hypochlorite

- Hydrochloric acid

- Sulfuric acid

- Phosphoric acid

- Sodium chloride

- Caustic soda

Where Can CPVC Be Used in Chemical Processing Plants?

With a wide chemical resistance range, superior performance attributes and extensive approval across key industry standards, CPVC is frequently specified in the following chemical processing applications:

- Potable water

- Reclaimed water

- Eye wash and shower stations

- Demineralized/Reverse Osmosis (DI/RO) water

- Condensate water transfer

- Facility unloading stations for key acids and bases

- Facility distribution

- Process transfer lines or injection lines for acids and bases

Learn More About CPVC Use in Chemical Processing Plants

Learn more about how CPVC can improve system reliability across many chemical processing applications in our ebook, CPVC Use In the Chemical Processing Industry.