Corzan® CPVC for Ducting Systems

Manufacturing integrated circuits (or chips) is a highly complex process that presents unique challenges for industrial piping systems. Toxic, highly corrosive and flammable gases and liquids can compromise a system’s integrity, causing process leaks and premature failure. In addition, few piping materials can meet the high purity standards required for cleanrooms.

The semiconductor industry represents the number one application for Corzan® chlorinated polyvinyl chloride (CPVC) duct, with most systems used to exhaust chemical fumes off the tools, which are the machines that make the processing chips. Corzan CPVC duct is also used in galvanizing and chrome plating applications within industries such as automotive and aircraft.

Balance of Properties for Greater Reliability

Corzan CPVC duct is able to perform in aggressive environments -- such as semiconductor fabrication plants – that are unsuitable for other types of piping systems. The material offers an outstanding balance of properties to boost reliability while reducing costly downtime and life-cycle costs.

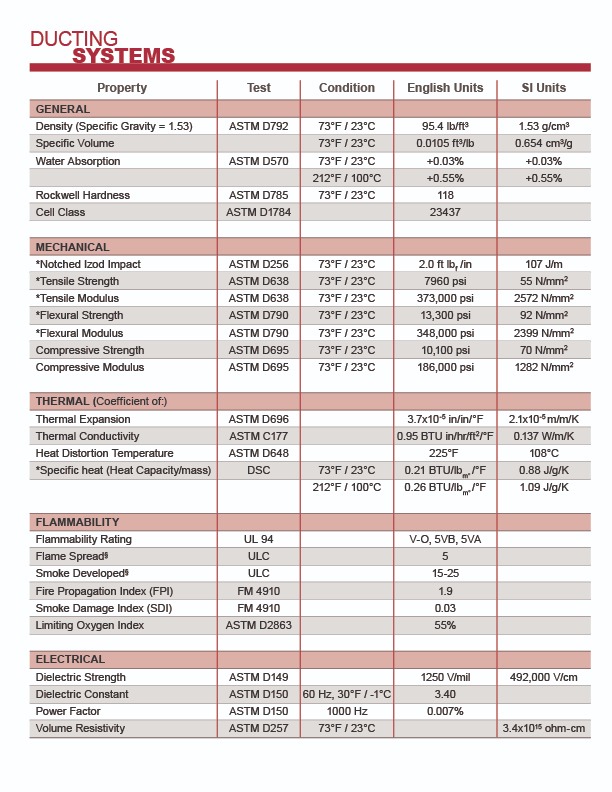

The chart below provides an analysis of Corzan CPVC ducting material. Well-balanced properties are essential to ensure the ducting material selected can handle application-specific requirements.

Ability to Withstand Aggressive Chemicals, High Temperatures

Ability to Withstand Aggressive Chemicals, High Temperatures

Nearly 60 different chemicals are utilized during the chip manufacturing process, including aggressive acids and bases such as sodium hydroxide. Facilities that depend on stainless steel pipe and duct generally line the steel with polytetrafluoroethylene (PTFE) and other Teflon materials.

Many semiconductor fabrication plants, however, are employing 24-inch and smaller Corzan CPVC duct to replace PTFE systems. Corzan CPVC chemically resists most acids, bases, salts, aliphatic solutions, oxidants and halogens to provide cost-effective, long-lasting solutions for hot corrosive fume and drain handling systems.

The Corzan CPVC Chemical Resistance Chart details Corzan CPVC’s compatibility with over 400 different chemicals. Information presented in the chart is based on test data and field experience of CPVC manufactured by Lubrizol Advanced Materials.

In addition, Corzan CPVC ducting materials have a cell classification of 23447 per ASTM D1784, which enables the systems to safely carry many corrosive chemicals at temperatures up to 200°F.

Mechanical Properties to Withstand Pressure Conditions

Excellent mechanical properties enable Corzan CPVC fume handling systems to withstand higher vacuum loadings and varying pressure conditions compared to traditional materials – especially at elevated temperatures.

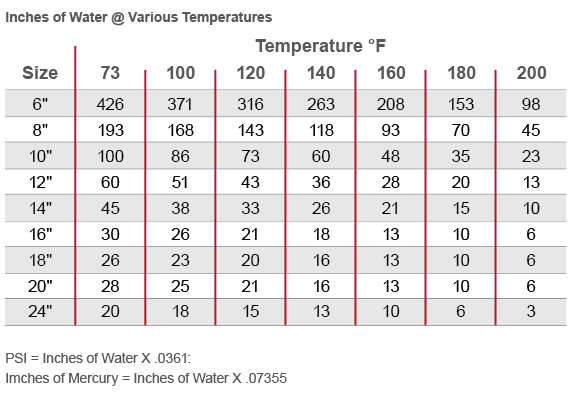

Testing conducted at an independent test facility confirmed that Corzan CPVC ducting performs well in the harsh conditions typical of most fume handling applications. During testing, Corzan CPVC duct was taken to extremes under negative pressure conditions to validate the product’s structural integrity at higher temperatures. The negative pressure ratings listed in the table below are for round seamless extruded CPVC duct at various temperatures using a 1.5:1 safety ratio.

Maximum Internal Negative Pressure Rating

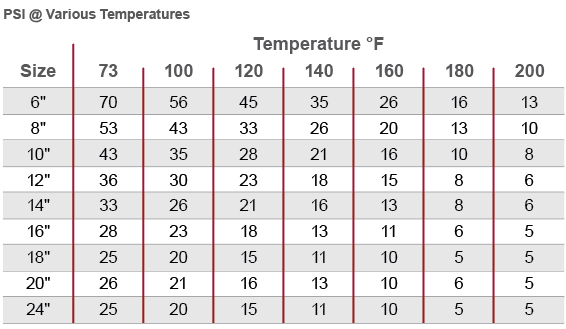

The following table includes the maximum recommended internal pressure rating in psi for Corzan CPVC round seamless extruded duct at various room temperatures.

Maximum Internal Positive Pressure Rating

The maximum values listed are for extruded duct pipe only and incorporate a 1.5:1 safety factor. Consideration should be given to the system design, method of fabrication and joining, which may require additional system derating.

The use of compressed air or gasses is not recommended for use with Corzan CPVC ducting.

Flammability Resistance for Increased Safety

Flammability resistance helps Corzan CPVC duct create a safer environment within semiconductor fabrication plants. Corzan CPVC duct material meets the American National Standard for Cleanroom Materials Flammability Test Protocol as set forth by Factory Mutual Approval 4910 for ducting, piping systems and sheet products.

With a high Limiting Oxygen Index (LOI) of 60 percent, Corzan CPVC duct will not supply fuel for a fire in the form of oxygen under normal atmospheric conditions. The instant a flame is extinguished from around Corzan CPVC pipe and duct, the material will self-extinguish and the burning will stop.

A burn test was conducted to confirm Corzan CPVC piping system’s response to flame. The video that follows shows how the material develops a protective char immediately after it is exposed to fire. This charring, which likewise occurs in Corzan CPVC duct, acts as a thermal barrier to reduce the rate of burning.

Corzan CPVC duct also offers exceptional low-flame spread and smoke generation properties.

Easy Installation

Lightweight Corzan CPVC duct can easily be assembled in the field using standard thermoplastic joining techniques. Installation requires no complex tools, electricity, highly skilled welders or heavy equipment.

A simple two-step solvent cement process is generally used to join belled-end duct, couplings, flanges and other socket-style fittings, creating highly reliable joints that become the system’s strongest part. Thermal welding is also a joining option and employs hot-air tools to fuse together Corzan CPVC seams to form one continuous piece of material.

Fewer hangers and supports are required for Corzan® CPVC duct at elevated temperatures compared to other thermoplastic duct. As with all piping systems, proper support spacing is critical to minimize deflection and sagging.

A Proven Solution

Corzan CPVC ducting systems are available in 6-inch through 24-inch diameters to provide cost-effective solutions for hot corrosive fume and drain handling systems in the rapidly expanding semiconductor industry and other markets. With over 60 years of operating success in harsh environments worldwide, Corzan CPVC has the properties to ensure reliable, long-term performance.

Corzan partner manufacturers GF Piping Systems and Harrison Machine & Plastics offer Corzan CPVC duct and other piping products. Contact a Corzan engineering expert or a partner manufacturer for engineering guidelines or to schedule a free process suitability review and technical assessment.

Details for this blog were taken in part from the following:

https://www.corzan.com/en-us/ducting

https://www.corzan.com/en-us/cpvc-semiconductor-and-electronics-industry