WHAT IS CPVC’S TEMPERATURE RATING?

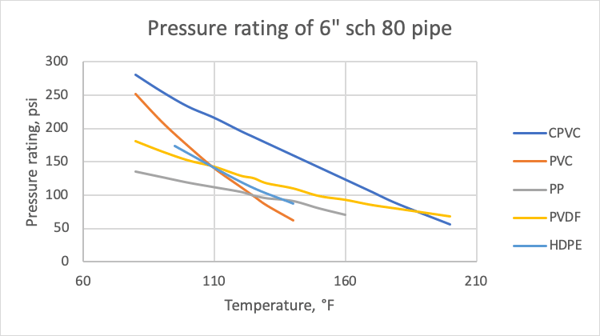

Corzan® chlorinated polyvinyl chloride (CPVC) offers the peace of mind that comes with a piping system that provides superior resistance to corrosive chemicals at high temperatures and pressures. Corzan CPVC can be used for pressurized service up to 200°F and offers a higher pressure rating over most of its useful temperature range than most of the other thermoplastic materials used for industrial piping. as illustrated in the chart below.

Other thermoplastic materials such as PVC, polypropylene or HDPE have a maximum pressurized service temperature as low as 140°F or 160°F. Some grades of HDPE may be pressure rated as high as 180°F, but their maximum pressure at elevated temperatures is low compared to Corzan CPVC. Facilities that install systems with higher maximum temperature and pressure ratings have more flexibility to deal with process fluctuations or the changes in operating conditions that eventually occur in most chemical processing applications.

How Thermoplastics’ Temperature Performance is Measured

How Thermoplastics’ Temperature Performance is Measured

When most people think of thermoplastics, they think of a melting temperature. It may be surprising that not all plastics have a melting temperature (Tm). Just like with other substances such as metals, ice, or sugar, a melting temperature is the temperature at which crystals break down and molecules or atoms begin to separate from each other. Some plastics, such as polypropylene, HDPE and PVDF can crystallize, and thus they have a melting temperature at the point at which those crystals break down. These are known as semi-crystalline materials.

Other plastics, such as CPVC, do not crystallize and thus do not have a melting temperature. These are known as amorphous materials. As amorphous materials such as CPVC heat up, they never actually melt. They do eventually reach a point where they transition from being hard and rigid to becoming soft and flexible. This temperature is called the glass transition temperature (Tg). Semi-crystalline materials also have a glass transition temperature. This is because they are only semi-crystalline – the rest of their structure is amorphous.

Semi-crystalline materials have a very high melting temperature and a very low glass transition temperature. This means that at normal use temperatures they are held together by their crystals, and the materials are flexible because the amorphous part is mobile (above the glass transition temperature). Amorphous materials like PVC and CPVC, on the other hand, have a very high glass transition temperature. This means that at normal use temperatures their molecules are immobile and locked in place, making these plastics rigid and inflexible.

The measurement that is most commonly used to determine the maximum use temperature is called the heat deflection temperature (HDT). This is the temperature at which the plastic will begin to deflect while supporting a small mechanical load. At 230°F, Corzan CPVC has a heat deflection temperature – and thus a maximum use temperature -- much greater than most other commonly used thermoplastic piping materials.

The table below shows the temperature performance of various thermoplastics used for industrial piping. These values are approximate and may vary by grade.

| Tm | Tg | HDT | |

| Corzan CPVC | * | 275°F | 230°F |

| PVC | * | 176°F | 167°F |

| HDPE | 300°F | -166°F | 140°F |

| PP | 320°F | -4°F | 140°F |

| PVDF | 350°F | -27°F | 257°F |

How the Pipe’s Pressure Rating is Determined at a Given Temperature

Learn about how CPVC pipe pressure ratings are calculated in our resource article "How CPVC Pipe Pressure Ratings Are Calculated.”

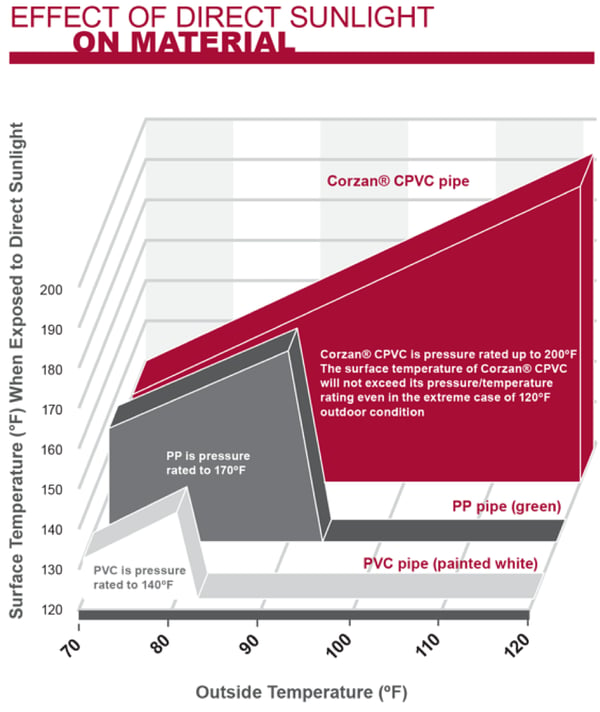

CPVC and Radiant Solar Heat

In outdoor installations, piping systems are often required to withstand extreme radiant heat. In some environments, the combination of radiant heat and ambient temperature can push a piping material past its maximum use temperature. The following chart shows the effect of direct sunlight on the Corzan CPVC surface temperature compared to other piping system materials. CPVC’s high maximum use temperature means that it retains its pressure-bearing performance even in the harshest of outdoor conditions.

Degradation due to UV exposure does not need to be a concern in outdoor installations. For more information on the weatherability performance of Corzan CPVC pipe, see our resource article “Corzan CPVC Piping Weatherability.”

Considerations for Designing Piping Systems

Considerations for Designing Piping Systems

All piping systems should be designed and installed according to the manufacturer’s instructions, taking into consideration factors such as operating temperature, pressure, flow requirements, friction loss, etc. Lubrizol works with a network of partner manufacturers that have a proven track record for providing high quality, reliable products. These manufacturers are carefully selected to convert Corzan CPVC into high performance piping systems, ducting sheets and lining that ensure long-term performance and low life-cycle costs.

For more information about Corzan CPVC’s maximum service temperature, HDT and ability to withstand UV exposure and radiant solar heat, contact one of our manufacturer partners or Corzan’s team of material experts who can answer questions and provide free technical consultation. Lubrizol Advanced Materials’ product and technical support is backed by 60 years of CPVC experience.

Details for this blog were taken, in part, from the following resources:

https://www.corzan.com/en-us/piping-systems

https://www.corzan.com/blog/what-you-need-to-know-about-cpvc-and-uv-weatherability