Corzan® CPVC Stands Up to the Elements

Many industrial environments such as the chemical processing industry, power generation plants, mineral processing and oil and gas operations use piping systems that are partially or completely installed outdoors. Piping systems used in outdoor applications must be able to maintain their basic physical properties after prolonged exposure to the elements – wind, rain/humidity, direct sunlight and seasonal and extreme temperatures.

During the past 60 years, Corzan® CPVC piping systems have proven they can withstand long-term environmental exposure without displaying significant adverse effects. Corzan CPVC piping, valves and ducting are designed for reliability and long-term performance in outdoor applications, ensuring greater productivity and lower life-cycle costs.

Prolonged UV Exposure and Radiant Heat

Thermoplastics such as CPVC are generally well suited to withstand the many challenges associated with ongoing exposure to the elements. Some thermoplastics, however, cannot tolerate the effects of ultraviolet radiation on piping. Too much exposure to UV light can weaken the materials’ inherent properties and limit key performance characteristics. In some installations, insufficient extrusion quality may result in inferior chemical resistance and mechanical performance.

Lubrizol works with our Corzan manufacturing partners to consistently provide a superior-finished material that exceeds consensus standards such as ASTM 441. The safety of our customers and their employees is extremely important as part of Corzan CPVC systems’ value proposition.

In addition, the extensive history of Corzan CPVC has proven the material’s superior performance in regards to impact strength and long term hydrostatic design stress capabilities. The use of significant concentrations of carbon black and titanium dioxide (TiO2), with both additives recognized as excellent ultraviolet blocking agents, have ensured decades of successful performance in outdoor conditions. The additives protect the pipe’s polymer backbone and enable it to retain its pressure rating, mechanical strength, impact resistance and other physical qualities, giving Corzan CPVC a best in class performance after extended UV exposure.

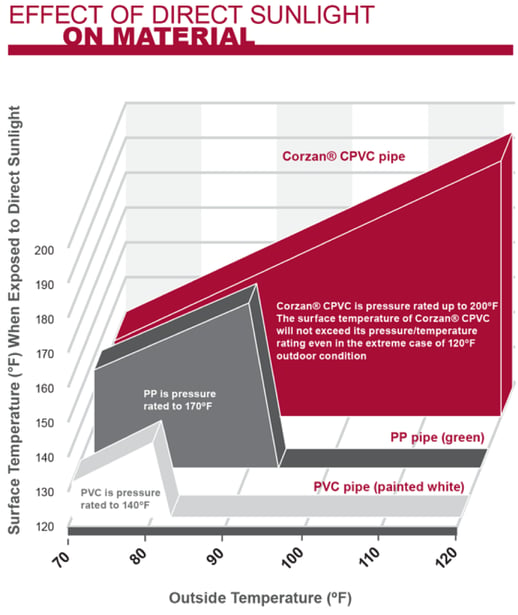

The graphic below shows the surface temperatures caused by direct sunlight on the Corzan CPVC pipe compared to other piping system materials.

Schedule 80 Corzan CPVC may display some discoloration on the pipe exterior over time, which is sometimes perceived as the UV exposure damaging the piping. In reality, discoloration is part of the material’s natural weathering process and is not detrimental to the piping system. If a cross section of pipe were removed, it would reveal that only the very top layer of piping is discolored. Depending on the installation, painting the piping with water-based latex paint will provide the additional UV resistance needed.

Piping systems must be able to withstand extreme heat caused by solar cycling. Observations of surface temperature during an ambient temperature day confirm the solar impact is enough to push PVC and PPR piping materials beyond their rated pressure at the elevated temperature.

Thermal Expansion

All thermoplastic piping systems must be designed and installed to accommodate thermal expansion. Temperature differential is the most important factor to consider when designing a piping system for an outdoor application. Temperature differential is the difference between the maximum and minimum temperatures the piping system will be exposed to over the course of its service life.

The expansion or contraction of thermoplastic piping may be calculated using the following formula:

Thermal Expansion Formula

ΔL = LpC ΔT

Where: ΔL = Change in length due to change in temperature (in.)

Lp = Length of pipe (in.)

C = Coefficient of thermal expansion (in./in./°F)

= 3.4 x 10-5 in./in./°F for CPVC

ΔT = Change in temperature (°F)

Generally, the piping system design should compensate for thermal expansion any time the total temperature change is greater than 30°F (17°C). Expansion loops, offsets or changes in direction may be included to accommodate thermal expansion.

Expansion Loop Formula

= 3 ED (ΔL)

2S

Where: = Loop length (in.)

E = Modulus of elasticity at maximum temperature (psi)

S = Working Stress at maximum temperature (psi)

D = Outside diameter of pipe (in.)

ΔL = Change in length due to change in temperature (in.)

Lubrizol offers the Corzan CPVC Expansion Calculator to aid in the design of a Corzan piping system. Designers/engineers enter the pipe diameter, maximum and minimum temperatures and pipe run length. The calculator will then show the linear expansion of the pipe and the necessary dimensions of expansion loops, offsets and changes of direction.

Expansion loops and offsets should include straight pipe and 90° elbows joined with solvent cement. Even if threaded pipe is used for the rest of the system, expansion loops and offsets should be constructed with solvent cement to increase their ability to handle the bending stresses that occur during expansion.

Low Temperatures and Freezing

Corzan CPVC has no known absolute minimum temperature for installation in outdoor environments. Corzan CPVC is an amorphous structured material that operates below the glass transition temperature (Tg) and, as such, does not have a freezing point.

The medium a Corzan piping system carries typically dictates the minimum temperature. Each medium has a freeze point at which heat tracing systems are required to protect the substance from extreme cold conditions. A general guideline of -15°F (-26°C) is typically used as the piping system’s lower limit.

Engineers and installers must pay particular attention to detail when installing any piping system in temperatures below 40°F. While CPVC has the ability to operate well below 40°F, it is essential to understand the engineering requirements and to properly train installers to ensure a successful installation. Contact one of our Corzan subject matter experts for assistance with piping system engineering.

Unavoidable Outdoor Piping Installations

Outdoor piping installations are sometimes unavoidable. Designers and engineers can look to Corzan CPVC to gain the performance advantages that ensure piping system reliability in outdoor applications – including resistance to UV weathering. Corzan CPVC piping, fittings and valves have been successfully installed in outdoor applications in various industries around the globe.

Request a consultation with a Corzan engineering expert or one of our manufacturing partners for assistance in specifying a durable and safe piping system or to schedule a free process suitability review and technical assessment.

Details for this blog were taken, in part, from the following:

https://www.corzan.com/en-us/piping-systems/specification/weatherability

https://www.corzan.com/blog/what-you-need-to-know-about-cpvc-and-uv-weatherability

https://www.corzan.com/blog/the-guide-to-cold-weather-cpvc-piping-installation