Where It’s Used: Power Generation Industry

The power generation industry has limited choices when specifying products or material for use in plant processes. The chosen piping solution and tank lining directly increases operational efficiency, minimizes downtime and ultimately improves bottom-line performance.

Highly durable Corzan® CPVC stands up to the unique challenges of the power generation industry over the long-term better than any other piping material, metallic or non-metallic. Corzan CPVC effectively stands up to most acids, bases and salts and aliphatic hydrocarbons commonly used in power generation plants including:

- Hypochlorite

- Caustic soda

- Sulfuric acid

- Sodium sulfite

- Ferrous chloride

- Ferric chloride

- Hydrogen sulfide

- Alum

A Solution the Power Generation Industry Trusts

Corzan Material and Piping Solutions have nearly 60 years of success in a wide array of processing applications around the world and offer a more reliable, cost-effective alternative to other plastic piping materials. Most Corzan CPVC industrial systems operate continuously for many years without interruptions due to leaks or repairs.

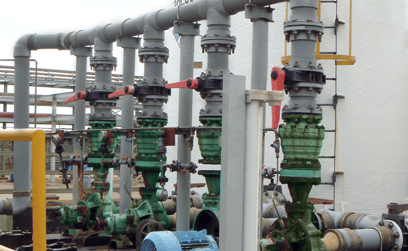

Corzan CPVC surpasses the performance and cost of other materials in power generation for:

- Underground cooling water loops

- Cooling tower risers and headers

- Demineralized water for boiler feed systems

- Condensate return water applications

- Flue gas desulfurization systems

- Environmental systems (for coal-fired steam plants)

- Wastewater treatment facilities

Corzan® CPVC's Use in Power Generation Plants

Corzan CPVC brings its proven track record of lower installation costs, superior chemical resistance, better ease of use and more to power generation plants.

Relevant Blog Posts

Design for Pipe Stress in Power Plants

How to Optimize Efficiency and Reliability in Power Generation Cooling Water Systems

Understanding Clean Air Compliance for Coal-Fired Power Plants

Why Metal is No Longer the Go-To Piping Material for Power Generation Facilities

Corzan® CPVC Reduces Power Plant Downtime and Maintenance Costs

Contact a Corzan CPVC Specialist

One of the many things that sets Corzan CPVC apart from the competition is our service. The Corzan CPVC team has a proven record of personalized, timely customer care. Get expert answers to your question to help make your project a success with Corzan CPVC.

Submit the form and an expert will be in touch within one business day.