Why Metal is No Longer the Go-To Piping Material for Power Generation Facilities

Processes within power generation plants must be reliable and efficient – especially since facilities cannot economically store electric power and must be online and produce power to meet demand. The need for high levels of reliability coupled with the ability to withstand the very harsh conditions present in most power generation plants is inciting designers to specify non-metallic pipe materials such as Corzan CPVC® to achieve long-term, cost-effective performance.

Corzan CPVC complete piping systems are made of specialty, high-performance material for durability and offer an excellent balance of properties to meet specific application requirements within new and existing power plants. Corzan Industrial Systems are applicable for almost every area, including underground cooling water loops, cooling tower risers and headers, boiler feeders, condensate return water systems, flue gas desulfurization systems, environmental systems for coal-fired steam plants and wastewater treatment facilities.

The systems may be installed underground and/or in elevated structures to help ensure power generation facilities remain operational and highly productive.

The Need to Eliminate Corrosion and Scaling

Corrosion is a major challenge for industries worldwide, with the global cost of corrosion surpassing $2.5 trillion each year, according to the results of a two-year NACE International study released during the CORROSION 2016 conference. Corrosion to pipes, fittings and valves caused by aggressive chemicals used in power plants such as hypochlorite, caustic soda, ferrous chloride, hydrogen sulfide and alum compromise the integrity of most metal piping systems – even expensive alloys and lined carbon steel.

Metal piping may undergo pitting corrosion, which causes tiny pits to form along the length of pipe that diminish the pipe’s wall thickness and reduce its pressure bearing capabilities. Crevice corrosion is also a concern as ions in the fluid concentrate in crevices around welds, flanges and other types of pipe connections. The resulting ion buildup can degrade the piping material quickly and cause leaks at welds and joints.

Power plant water treatment systems typically use chemicals such as sulfite-based oxygen scavengers that remove any trace of oxygen, which is a catalyst for corrosion. Phosphates added to the boiler feed water stream bind calcium ions and prevent them from attaching to metal parts, resulting in scaling that constricts the piping system and increases pressure. The consequences of corrosion and scaling instigate problems such as decreased pumping efficiency and contaminated fluid.

Unlike metal piping, Corzan CPVC is corrosion resistant and has a significantly lower affinity to scaling. As an engineered thermoplastic, Corzan CPVC is inert to most acids, bases and salts and provides superior, long-term resistance to corrosive chemicals, seawater and demineralized water – even at high temperatures. The Corzan CPVC Chemical Resistance Chart provides a comprehensive list of more than 400 chemicals and compounds that have been tested for their compatibility with Corzan CPVC.

Corzan Industrial Systems also have a Hazen Williams C Factor of 150, with the higher the rating, the lower the friction loss. The piping system will retain this rating throughout its life cycle compared to new cast iron, which has a rating of 120 and can drop to 60 to 80 when the material becomes worn or pitted.

An Alternative to Reduce Installation and Pipe Maintenance Costs

Labor, fabrication and other expenses can account for more than half of a piping system’s installed cost. Installing metal piping is especially time consuming and labor intensive as it involves a complex welding process requiring a designated welding area; an experienced, certified welder; costly hot work permits and weld x-rays.

In addition, metal piping is inflexible and even subtle adjustments to the system’s alignment may require expensive reconfigurations. Metal piping systems are heavy – approximately six times the weight of CPVC – and may require more laborers and heavy equipment to move and hoist the piping into place. The weight difference between a 50-foot section of 6-inch schedule 80 Corzan CPVC pipe and steel pipe of the same size, for example, is approximately 1,150 pounds.

Corzan CPVC is more flexible and easier to maneuver than metal piping, which speeds installation and maintenance, decreases downtime and reduces worker strain and injury. In addition, the thermoplastic is generally joined with a fast and easy two-step solvent cement welding process that can be performed by a trained mechanical contractor or a plant maintenance engineer. A solvent welded CPVC joint offers advantages such as greater strength and dependability and no loss of containment (LOC) issues.

Mechanical couplings can also be used to join CPVC to CPVC or CPVC to other piping materials, including metal. Victaulic mechanical joining solutions, for example, offer fast, easy joining options that increase safety, ensure reliability and maximize efficiency.

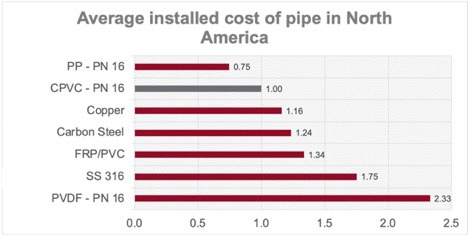

The following chart shows the installed cost of various types of piping systems, including Corzan CPVC and carbon steel.

Regular maintenance will be required for any piping system – whether a metal system or Corzan CPVC. Maintenance may include integrating a new piece of equipment into the system, altering the layout or replacing sections of pipe that are accidentally damaged.

Just as metal piping systems are more expensive to install, they will cost more to maintain than Corzan CPVC based on the metal system’s welding requirements, weight and inflexibility.

Piping System Advantages to Increase Performance

Progressive power generation plants are specifying Corzan Industrial Systems because they are made from high-performing CPVC to meet facilities’ ever-increasing demands. Besides eliminating corrosion, Corzan CPVC offers superior mechanical strength and the highest impact resistance (24448 cell class up to 8-inch diameter as defined by ASTM D1784) of any CPVC piping. Corzan CPVC’s drop impact strength is up to three times higher than that of standard CPVC pipe material.

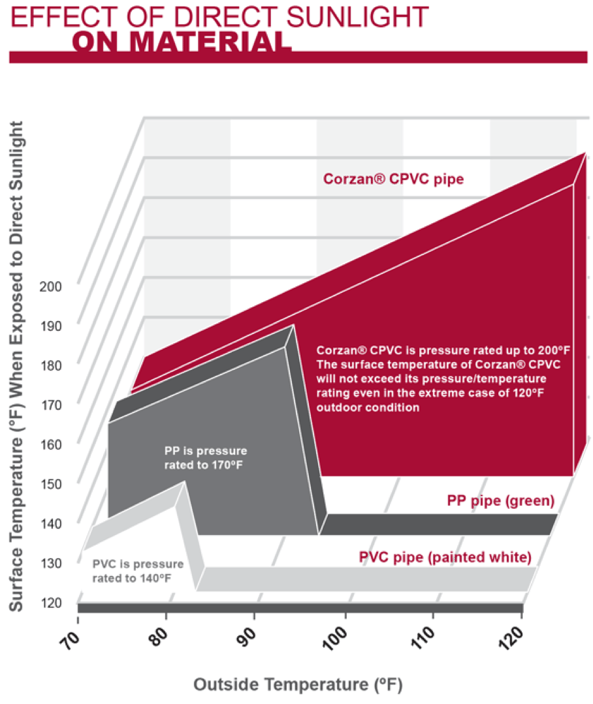

Corzan CPVC is also UV resistant, which is essential for power generation facilities that install piping systems partially or entirely outdoors, exposing the systems to temperature extremes and direct sunlight. The piping system incorporates significant quantities of carbon black and titanium dioxide to block ultraviolet rays. These additives protect the pipe’s polymer backbone so the material retains its pressure bearing capability even after extended UV exposure.

The graphic that follows illustrates the effect of direct sunlight on the Corzan CPVC surface temperature compared to other piping system materials.

At 230°F, Corzan CPVC Cell Class 24448 materials have the highest heat distortion temperature (HDT) in accordance with ASTM D1783 of any certified CPVC material.

At 230°F, Corzan CPVC Cell Class 24448 materials have the highest heat distortion temperature (HDT) in accordance with ASTM D1783 of any certified CPVC material.

Piping Systems that Perform

Highly durable Corzan CPVC complete systems have a proven 60-year history of successful performance across various industries and continues to provide the mechanical strength and corrosion prevention necessary for today’s power generation environments. Entire piping systems can be constructed of Corzan CPVC, with a single material for all components limiting complications, avoiding costly configuration workarounds and reducing overall capital and life cycles costs – especially when compared to stainless steel.

Corzan CPVC piping is available in diameters up to 24 inches to meet most power plant requirements, with Corzan pipe and fittings available globally through Lubrizol’s network of partner manufacturers. Contact a Corzan CPVC piping system expert to gain application engineering support or to schedule a free technical consultation.

Details for this blog were taken in part from the following:

https://www.corzan.com/en-us/cpvc-power-generation-industry

https://www.corzan.com/blog/design-requirements-for-power-generation-plant-cooling-systems

https://www.corzan.com/en-us/metal-v-cpvc-piping-systems