Hydrogen Production and the Role of Corzan® CPVC

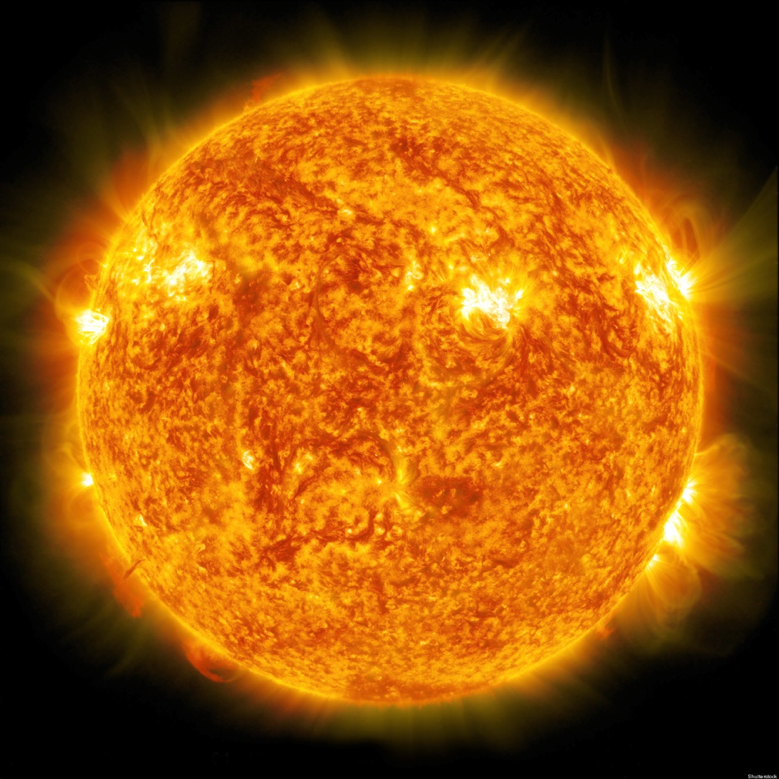

Hydrogen is essential for many industrial processes, from chemical production to oil refining to food and beverage industry use to powering vehicles as a fuel source. Multiple methods may be used to...